Hey, I said, have you ever had this experience - wanting to install a cool curved screen in the mall, but the solutions given by the supplier are like Lego building blocks? Or can you buy a transparent screen that costs a lot of money and become a "zebra crossing" after half a year? Don’t rush to pat your thighs. Today we will talk about this big thing: where to find a reliable LED special-shaped screen manufacturer?

1. The current situation of the industry is like the vegetable market

Now this industry is as messy as selling vegetables in the morning market. Look at a purchasing platform, there are more than 300 manufacturers in Shenzhen alone that claim to be able to make special-shaped screens. Some were doing light box advertisements yesterday, but today they could take orders for spherical screens. Last year, a customer found a small workshop with cheap pictures, but the joints of the cylindrical screen could be stuffed into his fingers, which turned into a water curtain hole on rainy days.

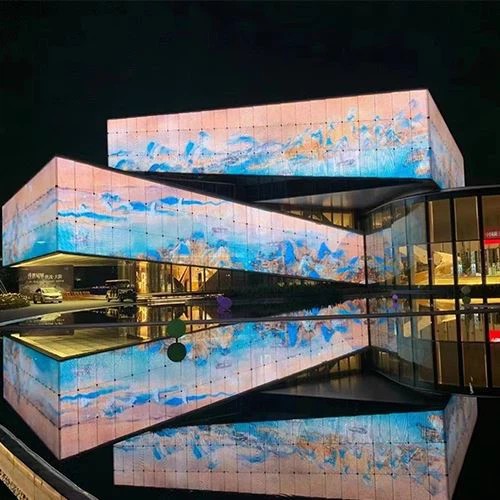

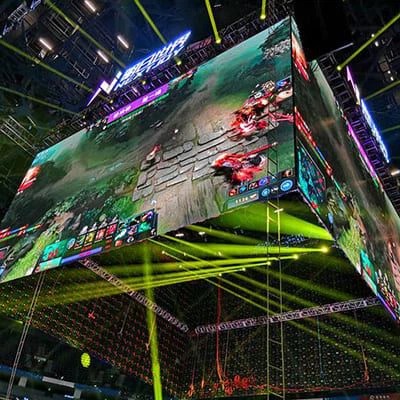

But then again, there are serious manufacturers. Like the fence screen we made for Tokyo Stadium, the IP65 protective box used is still as stable as an old dog in typhoon days. The key is to be able to pick a watermelon, just like you can take a few shots and listen to the sound.

2. Choose the three major hard-core indicators of the manufacturer

-

The technical foundation is more practical than the factory area

Don’t just listen to people’s praise for the fact that there are tens of thousands of square meters of factories. It depends on whether there is any independent display technology developed. For example, the low-bright high-gray technology can make the screen not reflective at noon and not dazzling in the middle of the night. This is the real kung fu. Our laboratory does an aging test, and the screen has to be baked in a 70-degree oven for 500 hours before passing the test.

-

Installation cases outperform renderings

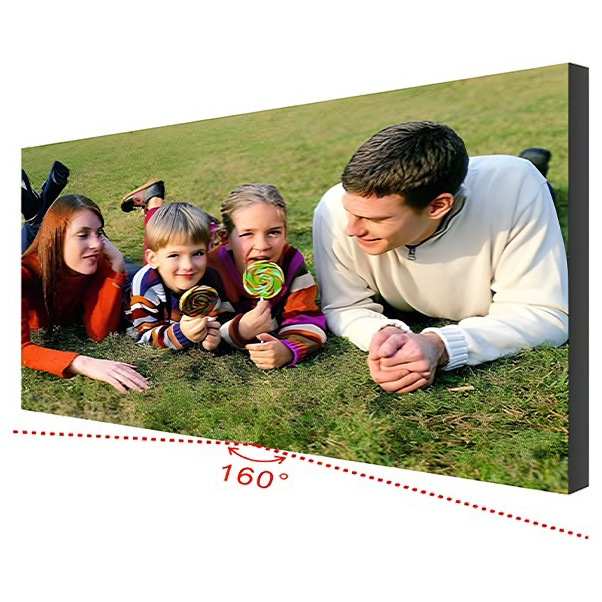

Just like when you are not allowed to just watch beauty photos on blind dates, you have to let the manufacturer post real videos. The focus is on two points: whether the splicing seams are treated like knife-cut tofu, and whether the surface arc error is within ±0.05°. The curved advertising screen we made for Singapore, the 56 special-shaped modules were finished, and the error in measuring with the vernier caliper did not exceed the thickness of the hair.

-

After-sales service is not a train

Many pitfalls occur three months after installation. A reliable manufacturer dares to write the contract in black and white: 2 hours of response, and comes with a backup module to the door. Our technical team flew 83 international flights last year, and the farthest to the South American Plateau to debug on site. The altitude of 4,000 meters was still solved on the same day.

3. How to break the price fog?

You must have encountered this - a transparent screen of the same size, Factory A reported 80,000 yuan, and Factory B dared to ask for 300,000 yuan. There are so many ways here:

- Material Cost: The price difference between ordinary glass and explosion-proof glass starts from 3 times. The aviation-grade aluminum-magnesium alloy frame we use is 40% more expensive than conventional materials but doubles its life

- Technical Solution: The smart temperature control system is 35% more expensive than the basic model, but it can save half of the electricity bill

- Certification Fees: Just doing CE certification requires more than 100,000 yuan, and the small workshop is reluctant to pay this money

To give a bloody example: a chain hotel bought a low-end floor tiles screen with a bargain, but the three-year maintenance fee was 120,000 more than the purchase money saved at the beginning. Therefore, buying a special-shaped screen requires a full life cycle account, and you cannot just look at the little money in front of you.

Self-question time

Q: Can you buy those spherical screens with a price of 20,000 yuan on the Internet?

A: This is just like shopping for "military mobile phones" online - you don't want to sell them casually if you really use military products! If you have a serious custom spherical screen, the optical structure design fee will account for 20% of the cost. Here’s a trick for you: let the manufacturer provide 72-hour continuous playback of test videos, and only those who can withstand the black screen and not stutter will pass.

Q: How to verify that the manufacturer is a real boss?

A: He has two professional questions: ① How to deal with thermal expansion and contraction between the box joints? ②Can it provide a five-year brightness attenuation curve? Each batch of goods comes with a national laboratory test report, and the data is spread out for you.

Q: Is it reliable to find a domestic manufacturer for overseas projects?

A: This depends on the global service capabilities. The projects we have done for Southeast Asia are made of 316 stainless steel for screws, and we have also specially developed salt spray coatings. During the acceptance, the local engineer took the laser rangefinder for half a day, and the result was that the error was 0.1mm smaller than the contract required.

4. Hidden knowledge points for installation and maintenance

Last year, I encountered a strange problem when installing screens for chemical factories - signal transmission in explosion-proof areas. Finally, an optical fiber isolation solution was used, and a three-level explosion-proof junction box was added in the middle. Here are some key points to save lives:

- The wire must be threaded through metal pipes, and the plastic sleeve is a time bomb at high temperature.

- The distribution box is at least 5 meters away from the hazardous source, and it is best to be installed on the outside of the isolation wall.

- You have to do airtightness tests twice a year, so you must not save this money

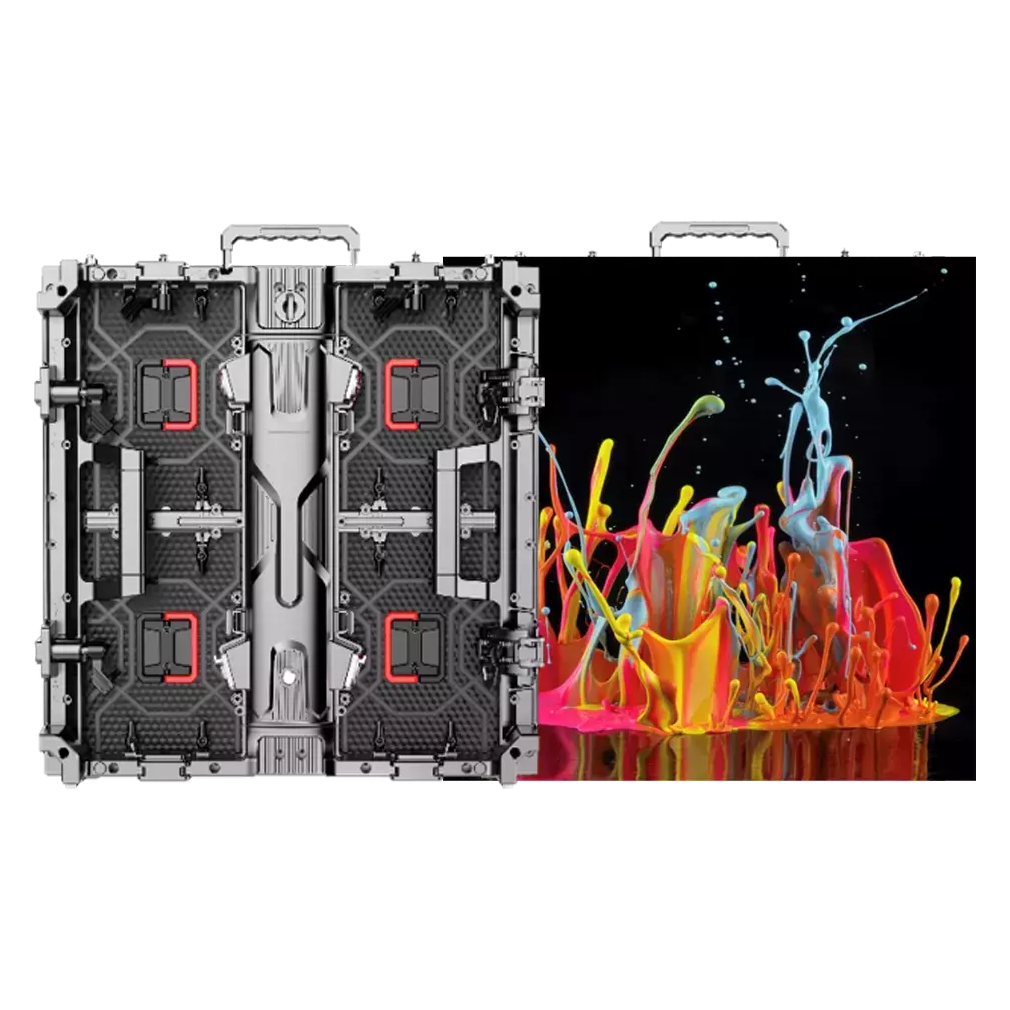

- Modular design is so important! Our latest special-shaped screen module replacement is faster than changing light bulbs

The editor finally said that it is heart-wrenching: looking for LED special-shaped screen manufacturers is like finding a partner. You can’t just look at the appearance (display effect), but you have to look at the financial situation (technical reserve), temperament (service system), and risk resistance (quality control). Next time I inspect the manufacturer, remember to take someone who knows what he knows about it to go to their workshop - machines can be bought, and the work that the master can do is not something that can be practiced in three or two days!